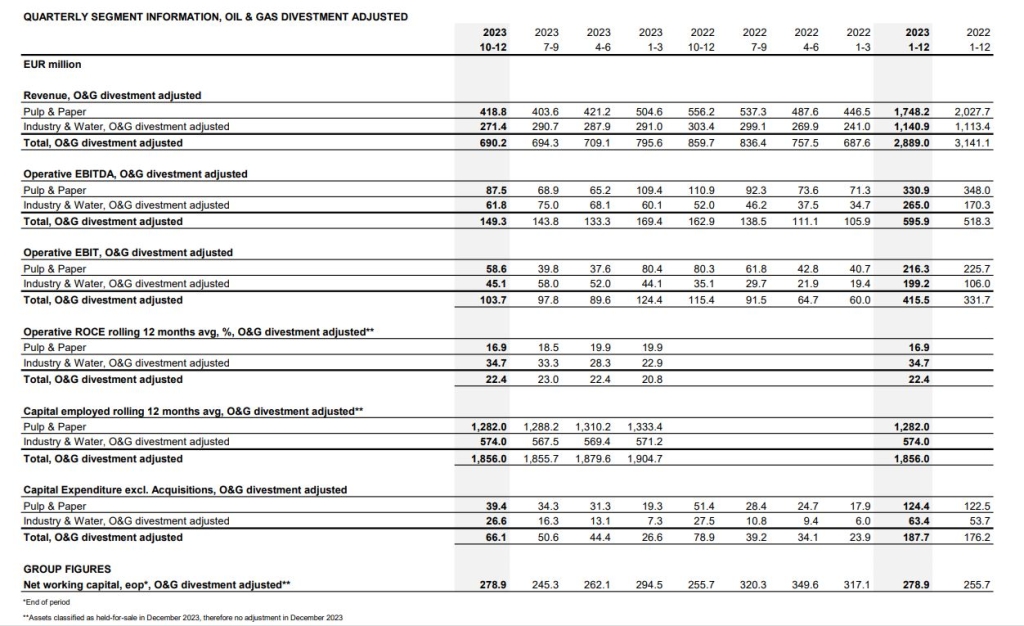

Kemira completed the divestment of its Oil & Gas related portfolio

On February 2, 2024 Kemira announced it has completed the divestment of its Oil & Gas related portfolio to Sterling Specialty Chemicals LLC, a US subsidiary of Artek Group, a global industrial chemicals group based in India. The divestment was announced on December 4, 2023.

The transaction enables Kemira to focus on its core businesses and accelerate its profitable growth strategy by focusing on growing in water treatment, building a leading renewable solutions portfolio and creating a digital services business.