Germany’s largest municipal wastewater treatment plant chooses biomass-balanced polymers

Wastewater treatment operations need to become more sustainable. Finding a way to reduce the carbon footprint, while maintaining stable performance in a sensitive process, is a challenging task. Good news is, there are smooth and safe solutions, implemented quickly to have an immediate impact. Read the story of Hamburg Wasser, a forerunner in sustainable wastewater treatment.

Article takeaways

Biomass-balanced polymers do not require full-scale trials, and can replace fossil-based polymers without comprising performance.

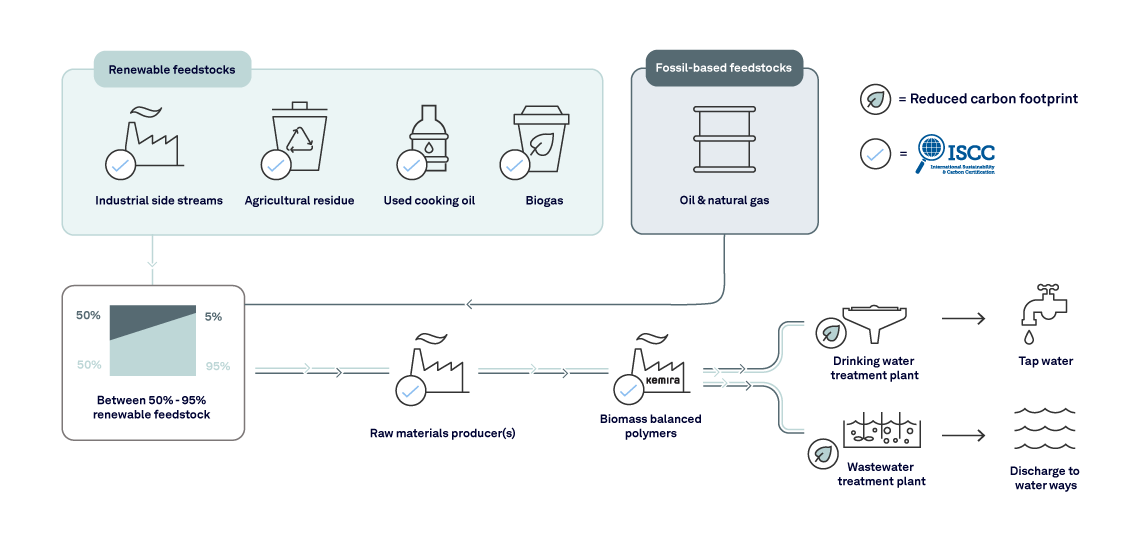

Biomass-balance increases the share of renewable feedstocks, while reducing fossil-feedstocks. This improves environmental impact and lowers carbon footprint, while maintaining product quality.

Hamburg Wasser in numbers

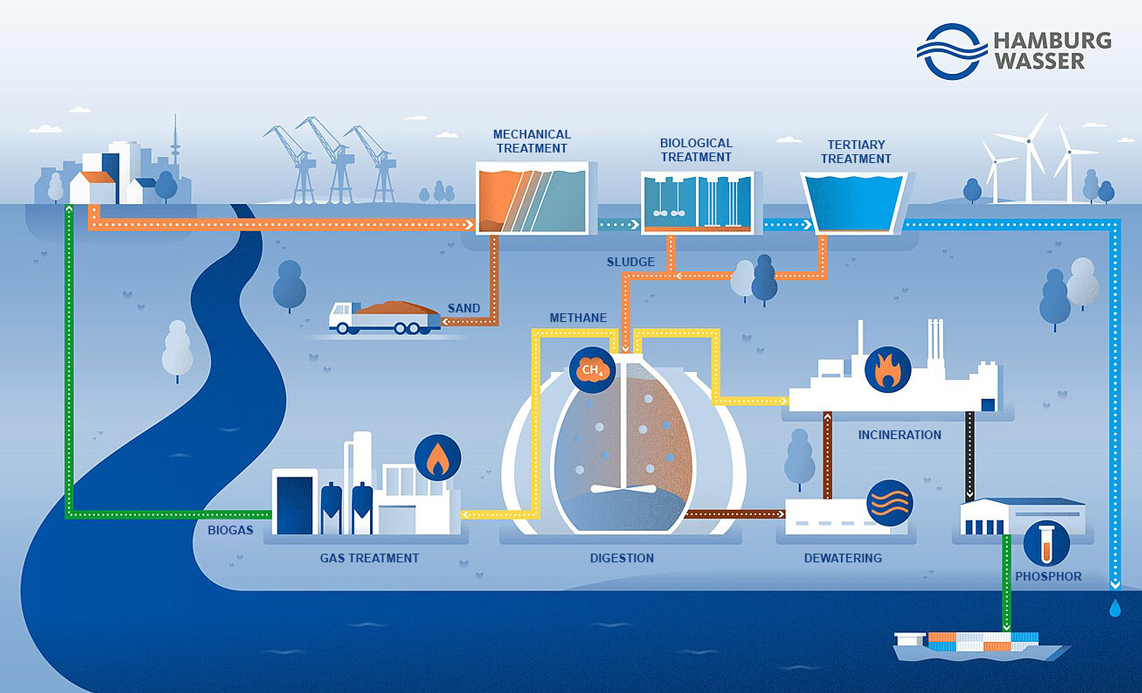

The wastewater treatment plant in the city of Hamburg is the largest in Germany, treating 340,000 cubic meters of wastewater on an average day, which is the equivalent of a 2.3 million population. The plant is located right in the center of Hamburg, in one of the busiest ports in the world. The utility operates a combined biological and chemical treatment with an integrated biogas production and sludge incineration facility.

The impressive digesters have been part of Hamburg’s iconic harbor landscape for decades, processing 4,000 m3 of sludge each day. The plant is generating regional and climate-neutral heating for around 5,700 households in Hamburg. The digested, dried sludge is incinerated on site, producing 89,000 MWh of electricity per year. Hamburg Wasser is already one of the most sustainable and energy efficient municipalities in Europe, but the aim is to become regenerative energy self-sufficient by the year 2030.

In 2024 Hamburg Wasser made a conscious decision to switch from conventional fossil-based polymers in their sludge thickening process, to Kemira´s new Superfloc® BioMB, to enforce their sustainability performance.

Implementing the biomass-balanced polymer was a low-hanging fruit, as it is a seamless switch from the conventional, fossil-based product, with exactly equal performance but a lower carbon footprint. It is a small but important step towards more sustainable operations.

Kemira is the first chemical manufacturer to offer a range of renewable polymers, in the polyacrylamides product line, helping water-intensive industries to make their processes more sustainable, without any compromise in performance. This product line is manufactured according to the principles of biomass balance, in which the majority of fossil-based raw materials are replaced by ISCC Plus certified biobased and renewable mass-balanced feedstocks.

The ISCC – International Sustainability and Carbon Certification (ISCC) is one of the world’s leading certification schemes, providing solutions for the implementation and certification of sustainable and traceable supply chains. It covers all sustainable feedstocks, including agricultural and forestry biomass, circular materials and renewables.

If you would like to hear more customer cases from other utilities shifting away from conventional fossil-based polymers, toward renewable solutions, watch our free on-demand Webinar.

Other stories you might like

Case studyWaterInnovation

Tallinn chooses biomass-balanced polymers for sludge dewatering

As an additional measure to make operations more sustainable, the Paljasaare wastewater treatment plant in Estonia´s capital city Tallinn decided to switch from conventional fossil-based Polymers to a renewable, biomass-balanced alternative product.

Read more

ArticleWaterWater

New bio-flocculants for water utilities

When wastewater treatment plants make the switch to biobased polymers, it can be a win for the planet. But what about performance? New Superfloc® BioMB, the world’s first line of biomass balanced flocculants, offers reliable performance and clear sustainability benefits.

Read more

Biogas & bioethanol

Chemical flocculants

Polymers are chemicals used in flocculation. Flocculation is the process of agglomerating destabilized particles into bigger flocs. In wastewater flocculation and sludge treatment, colloidal particles are flocked in order to aid their removal or to help sludge dewatering. Polymers can be used alone or together with inorganic coagulants to make flocs bigger and more resistant to shear forces.

Read more