Textile fiber innovation takes on the industry’s challenges with the help of chemical expertise

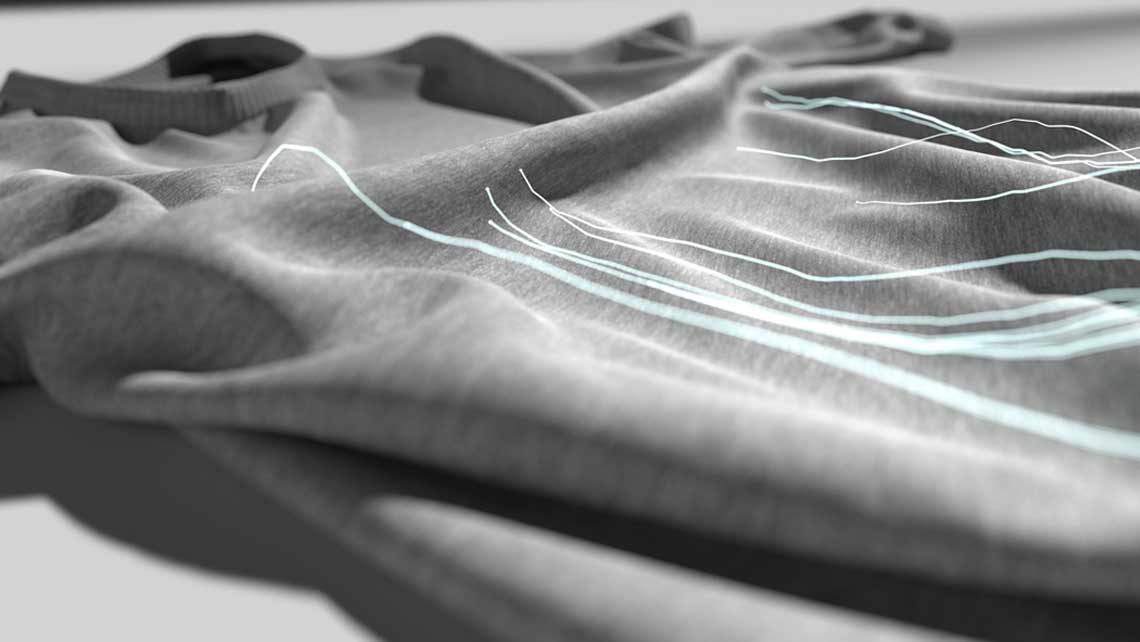

Fast fashion is a problem the world is trying to solve. Individual choices can only do so much – the industry needs to offer solutions, too. Wouldn’t it be great if we had other materials available than water-intensive cotton or fossil-based polyester? Read the story of how Metsä Group takes on the problem with the development of new fiber called Kuura™, made out of wood, with the help of chemistry expertise.

Article takeaways

Textile fiber production has similar issues to solve as pulp production. Both are water-based processes and require special chemistry to make the process efficient and safe.

New innovations are required to answer the growing demand of textile fibers globally and to solve the environmental problems caused by fossil-based polyester and water-intensive cotton production.

The global demand for textile fibers increases annually, driven by growing populations and changing consumer behaviors. Kemira’s objective is to become a key enabler of more sustainable and efficient textile fiber production and to grow together with partners in this field, helping scale up sustainable alternatives that can meet the demands of a global textile market.

Metsä Group’s innovation company, Metsä Spring, is developing a new lyocell-type fiber made of Finnish softwood, called Kuura™. Currently Metsä Group is investigating the potential for launching the Kuura business in an ongoing pre-engineering project. Kemira has been chosen as the main chemistry partner in the project. Since Kemira and Metsä Group have been collaborating for ages, with Kemira providing end-to-end chemistry packages to Metsä Group’s water intensive processes, it was a natural choice.

Metsä Spring’s CEO Niklas von Weymarn and Kemira’s New Ventures & Services Vice President, Commercial, Riikka Timonen, explain the ins and outs of Kuura™ fibre collaboration.

Chemistry expertise enables scale-up

The collaboration between Kemira and Metsä Group enables process feasibility and scale up of the fiber production. In Metsä Group’s industrial concept, the Kuura mill would be integrated to Metsä Group’s existing paper pulp production. Kemira helps Metsä Group maintain high cleanliness across the entire water-based process, which is essential for both operational efficiency and fiber quality. Kemira’s solutions bleach the fibers and provide spinfinish chemistry to the end product.

The demand for new cellulosic materials in the textile industry is clear. According to the Textile Exchange’s annual Materials Market Report 2024, global annual textile fiber production will reach 160 million tonnes by 2030. Currently over 50% of total global fiber production is polyester, a synthetic fiber made of oil that causes serious environmental problems, like contributing majorly to microplastics pollution. The second-most used raw material is cotton, which requires not only huge amounts of water and land to produce, but also pesticides and fertilisers. New fiber innovations can ease the burden on the enrvironment.

Global textile production in numbers

In 2023

124 million tonnes

of textiles were produced globally

Up to

700,000

microplastic fibers can be discharged in a single laundry load of synthetic fabrics

To make a single cotton shirt,

2,700 liters

litres of clean water is required

Other stories you might like

ArticleFiber-based materialsTextile fibers

Accelerating the sustainable development of the textile industry

The fashion industry faces a huge challenge in reaching its set targets for decarbonization and emission reduction. Novel man-made cellulosic fibers and efficient textile recycling are pivotal in the journey toward a more sustainable industry. But what topics dominate the discussions when stakeholders across the value chain gather to address the challenges and opportunities of this transformation?

Read more

ArticleFiber-based materialsTextile fibers

Renewing textiles: Chemistry expertise enables sustainability transformation

The textile industry is grappling with urgent challenges. We need to find more sustainable ways to produce and reuse textiles. In this transformation, renewable cellulose-based raw materials and textile recycling have a vital role. To unlock their true potential, chemistry expertise is key.

Read more