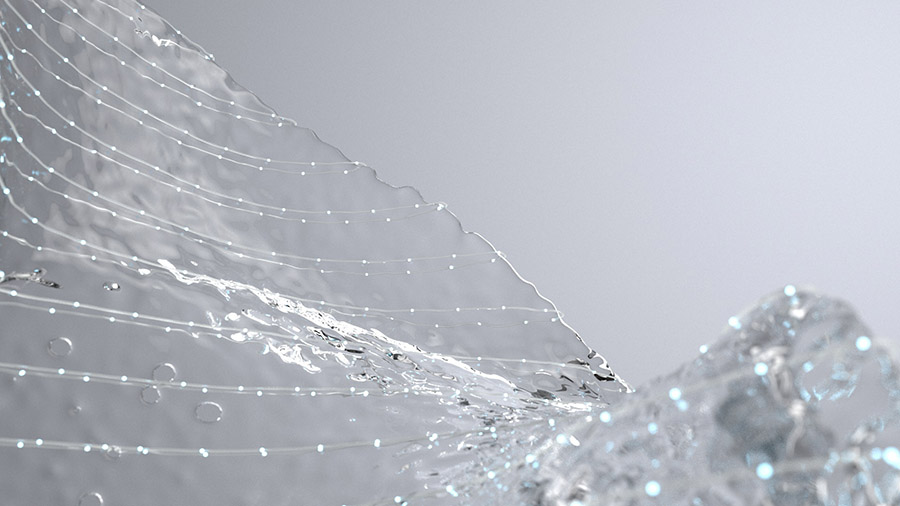

Data-driven chemistry management

The digital services we offer our customers today are built on our over 100 years of expertise in chemical products and application know-how.

We have developed unique, real-time monitoring and control technologies for chemistry applications to support performance optimization, fast troubleshooting, and continuous improvement.